I’m pleased to announce that SOLIDWORKS Model Based Definition (MBD) 2015 was released this week! Many people asked me what is MBD and why. These two images explain it well, and you tell me which one is easier to read?

Clearly the second one conveys design intent more effectively because we live in a 3D world and our brains naturally think in 3D. Traditional 2D engineering drawings have been serving us well in the past more than 200 years, but they also present many challenges:

Now we can. SOLIDWORKS MBD is built specifically to answer the above problems. It is an integrated drawingless manufacturing solution for SOLIDWORKS. It helps companies define, organize, and publish 3D Product Manufacturing Information (PMI) in industry standard file formats such as eDrawings® and 3D PDF. Unlike traditional 2D drawings, SOLIDWORKS MBD guides the manufacturing process directly in 3D, which helps streamline production, cut cycle time, reduce errors, and support industry standards such as Military-Standard-31000A, ASME Y14.41, ISO 16792, DIN ISO 16792, and GB 24734.

SOLIDWORKS MBD provides 3 key capabilities:

To learn more about SOLIDWORKS MBD, please visit the product pages.

Clearly the second one conveys design intent more effectively because we live in a 3D world and our brains naturally think in 3D. Traditional 2D engineering drawings have been serving us well in the past more than 200 years, but they also present many challenges:

- Counterintuitive by definition,

- prone to errors in creation and consumption,

- expensive to produce and maintain,

- easy to mismatch with 3D design,

- incompatible with highly productive 3D applications such as simulation and 3D printing,

Now we can. SOLIDWORKS MBD is built specifically to answer the above problems. It is an integrated drawingless manufacturing solution for SOLIDWORKS. It helps companies define, organize, and publish 3D Product Manufacturing Information (PMI) in industry standard file formats such as eDrawings® and 3D PDF. Unlike traditional 2D drawings, SOLIDWORKS MBD guides the manufacturing process directly in 3D, which helps streamline production, cut cycle time, reduce errors, and support industry standards such as Military-Standard-31000A, ASME Y14.41, ISO 16792, DIN ISO 16792, and GB 24734.

SOLIDWORKS MBD provides 3 key capabilities:

- Intelligent and semantic 3D PMI definition and organization. To help engineers define 3D dimensions and tolerances, we built in hundreds intelligent GD&T rules in the background guiding this definition process. Furthermore, to avoid massive overlapping 3D PMI or so-called “fur-ball” issue, SOLIDWORKS MBD features intuitive and patent-pending organization technologies such as 3D Views and Dynamic Annotation Views shown in Figure 2.

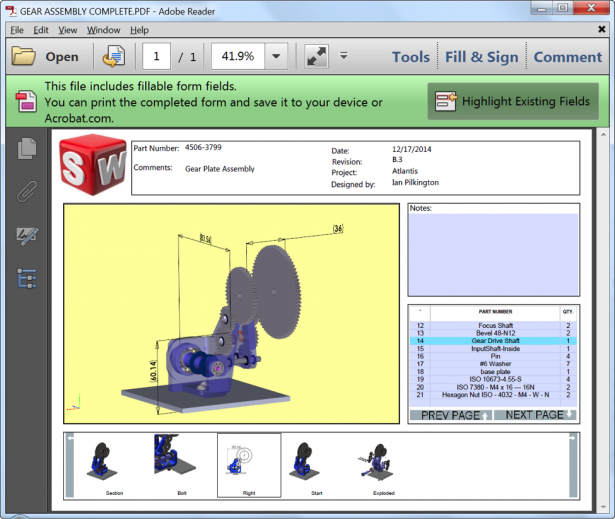

- 3D PMI publishing. As proven by MBD pioneer companies like Brazilian furniture manufacturer Viecelli Móveis or U.S. manufacturer of custom handling and packaging systems Automatic Handling International, the majority of MBD benefits come from downstream production and supply chain. We publish 3D PMI into eDrawings and 3D PDF (Figure 3.1 and 3.2) to enable downstream to fully leverage 3D data. Also, SOLIDWORKS MBD 3D PDF is based on the advanced PRC format which was just established as an ISO standard 14739: 2014. It’s accurate for measuring and machining, rich in information, and compact for easier distribution.

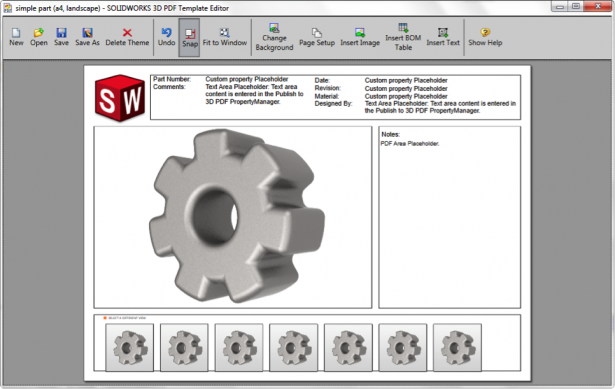

- Friendly 3D PDF template customization. To further facilitate downstream 3D data consumption, we also provide a 3D PDF template editor to tailor 3D PDF for multiple use cases or different teams, such as 3D PDF for part or assembly, Request for Quote, or machine part templates for remote shops. We can easily insert company logos or map product meta-properties into 3D PDF.

To learn more about SOLIDWORKS MBD, please visit the product pages.

0 comments:

Post a Comment

Note: only a member of this blog may post a comment.